B1.2 Hot water

Hot water is essential for daily living, particularly for washing people and cleaning. When selecting hot water systems, consider the residents’ needs, household population, climate, water quality, energy usage, type, and both the capital cost and the running cost of the system. Hot water system capacity should be based on peak demand times in each household and a minimum of 50 litres of hot water per person per day, at a temperature of 50 to 60°C[1], is suggested as a guide for working out the hot water system size.

An inefficient hot water system can put a strain on the household’s budget and at least half of the household energy bill can be spent heating water. People on a low income may not be able to afford to pay high energy bills and this can result in loss of power and subsequent loss of hot water. Consider using solar or gas systems that do not rely solely on electrical power and, if using an electric system, aim for an efficiency of at least 50 litres of hot water for every kilowatt hour of electricity used.

Water that is too hot can cause severe burns, particularly to children and elderly people. It is a mandatory requirement in some countries (Australia) that hot water systems in new houses, and if major changes are made to the plumbing of existing houses, that hot water systems are fitted with tempering valves that control the water temperature to all washing points in the house.

Hot water should be stored at no less than 60°C to prevent growth of harmful organisms; the hot water temperature at the shower, bathtub and hand basin should be tempered to a maximum of 50°C to prevent scalding; a minimum hot water temperature of 45°C is required at all hot water outlets allowing for temperature loss between the hot water system and the outlets.

Poor quality water that impacts on the function and durability of hot water systems. Water quality directly affects operational and maintenance costs because of the need for frequent replacement of hot water system elements, valves and associated parts. It is important to carefully research and specify all components of the hot water system including the material of the storage tank, specific element size and material, sacrificial anode type and suitability, relief valves and their pressure tolerance, tempering valves and solar panels (if applicable) to achieve the best outcome for the local water quality.

Data show that just under half of all hot water systems installed (46 per cent) are solely electrically powered and have large capacity heating elements. Whilst 84 per cent of these systems were able to deliver water at temperatures above the required 45ºC, over half (51 per cent) were producing water above 62ºC, increasing both the risk of burns and the energy cost of running the house.

Solar hot water systems were the second most common system type (47 per cent a gain of 7% since 2006).

Whilst 67 per cent of these systems were able to deliver water at temperatures above the required 45ºC, only 15 per cent were producing water above 62ºC, significantly reducing both the risk of burns and the energy cost of running the house. Most solar systems have electrical boosters to supplement the solar energy.

Other types of hot water system such as gas, heat pump and solid fuel systems comprised only 6 per cent of all systems and since 2006 there has been no change in the number of houses with no hot water system (2 per cent).

Survey data shows that hot water pressure relief valves continued to be a maintenance issues with 73 per cent functioning. Since 2006 there has been a 1 per cent decrease in the number of valves functioning. Faulty pressure relief valves waste hot water and residents’ money, as well as being a possible safety risk.

Real world examples of problems

-

Solar hot water unit overshadowed by trees

Solar hot water unit overshadowed by trees -

Solar hot water panels need to be facing the sun correctly

Solar hot water panels need to be facing the sun correctly -

Cover missing from instantaneous gas hot water unit

Cover missing from instantaneous gas hot water unit -

Working valves are important for the maintenance of hot water units. Here the valves have corroded in poor quality water.

Working valves are important for the maintenance of hot water units. Here the valves have corroded in poor quality water. -

Due to corrosion from poor quality water the storage tank has split releasing hot water

Due to corrosion from poor quality water the storage tank has split releasing hot water -

Water quality can effect heating elements

Water quality can effect heating elements -

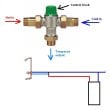

Duo Valve

Duo Valve -

Failure of duo valve, due to mineral salts in the water.

Failure of duo valve, due to mineral salts in the water. -

Water quality can effect heating elements

Water quality can effect heating elements -

Water quality can effect many components of hot water units

Water quality can effect many components of hot water units -

Split tank to hot water unit, note the water stains down the cylinder.

Split tank to hot water unit, note the water stains down the cylinder. -

2 electric hot water system elements - one new and a similar element after 2 weeks exposure to high mineral salt water.

2 electric hot water system elements - one new and a similar element after 2 weeks exposure to high mineral salt water.

-

Design and Specification

Ensure

- B1.2.1.

will deliver at least 400 litres of hot water, including recharges, at a minimum temperature of 45°C at hot water tap points around the house during a 24-hour period

- B1.2.2.

stores hot water at a minimum temperature of 60°C

- B1.2.3.

will provide hot water at peak demand times regardless of weather conditions

- B1.2.4.

will operate with the available water pressure ―this is particularly important for places with low pressure and for low pressure systems

- B1.2.5.

function efficiently in relation to variable water quality

- B1.2.6.

function in the variable climatic conditions

- B1.2.7.

is located close to the shower

- B1.2.8.

has an adequate re-charge time, on gas or electric units, that will deliver the required quantity of hot water

- B1.2.9.

if the hot water system has a pressure relief valve that is roof mounted ensure that it discharges to a ‘tundish’ or drain and not onto the roof, as high levels of mineral salts and/or the copper in the hot water system will corrode the roofing and gutters

- B1.2.10.

if it is a ground level hot water system, is installed on a plastic tray, on a concrete or masonry pad, rather than timber or steel frames which can deteriorate rapidly

- B1.2.11.

has supply pipes that are ‘lagged’ (insulated) from hot water system to tap points to improve efficiency. In cold climates (sub-zero degrees) lagg all exposed water supply lines (all materials), both hot and cold water pipes, to prevent them freezing and bursting. This can occur due to fluctuations in temperature

- B1.2.12.

tempering valves where required and installed are suited to local water conditions, are specified and are located in a valve box that is easily accessible for maintenance and adjustment

- B1.2.13.

tempering valves control water temperature to basin, bath and shower outlets

- B1.2.14.

the temperature of the hot water to the kitchen sink and laundry area is not tempered as hot water can be useful in breaking down grease in kitchen sink drainage

- B1.2.15.

to insulate pipes under the sink to allow for safe use of under bench area by disabled people if cupboards are removed

- B1.2.16.

an electrical isolation switch is provided for disconnecting the power for the safe maintenance of roof mounted systems

- B1.2.17.

instantaneous gas hot water systems have an automatic ignition rather than a pilot light to conserve gas

- B1.2.18.

the hot water system is fitted in accordance with local regulations.

Consider

In areas where water quality is poor, consider:

- providing to manufacturers water quality data, information regarding water pressure, and climatic conditions and obtaining their advice and warrantee on the best suited system

- specifying a sacrificial anode and element suited to the specific water quality

- using electric elements of less than 2400 watts because larger capacity elements have a quicker rate of calcification

- using ‘jacketed’ solar hot water systems with heat exchange fluids in the panels rather than using local poor quality water

- installing a removable metre length of metal pipe on the hot water supply side of the system that can easily be replaced when it becomes calcified.

- using an electric element of less than 2400 watts because larger elements can significantly increase running costs

- off-peak electricity but make certain the hot water system can meet demand between heating cycles and the storage tank is well insulated

- solar systems with a ‘one-shot’ booster switch that heats the water to a set temperature then automatically turns off. Locate the 'one-shot' booster inside the house in an easily accessible location and height (between 900 and 1100mm above floor level)

- heat pump or heat exchange system where access to a refrigeration mechanic is available.

Consider energy saving measures such as:

- using an electric element of less than 2400 watts because larger elements can significantly increase running costs

- off-peak electricity but make certain the hot water system can meet demand between heating cycles and the storage tank is well insulated

- solar systems with a ‘one-shot’ booster switch that heats the water to a set temperature then automatically turns off

- heat pump or heat exchange system where access to a refrigeration mechanic is available.

Real world examples of Solutions

-

Local community maintenance team tests hot water temperature regularly

Local community maintenance team tests hot water temperature regularly -

Protection of solar hot water panels

Protection of solar hot water panels -

Gas hot water unit with electronic ignition

Gas hot water unit with electronic ignition -

Polycarbonate enclosure to gas hot water unit

Polycarbonate enclosure to gas hot water unit -

Solar hot water booster switch

Solar hot water booster switch -

Wood chip type hot water unit can provide hot water backup when the main unit fails.

Wood chip type hot water unit can provide hot water backup when the main unit fails. -

Heat pump type hot water unit

Heat pump type hot water unit -

Accessible wall mounted valves to the roof mounted solar hot water unit

Accessible wall mounted valves to the roof mounted solar hot water unit -

Accessible valves to solar hot water unit

Accessible valves to solar hot water unit -

Pressure relief valve

Pressure relief valve -

Isolation valve

Isolation valve -

Electric hot water manufacturer's labelling will describe the volume, energy use and age of the system

Electric hot water manufacturer's labelling will describe the volume, energy use and age of the system -

Electric hot water unit

Electric hot water unit -

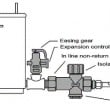

Isolating ball valve and back flow prevention

Isolating ball valve and back flow prevention -

Solar hot water one shot booster switch

Solar hot water one shot booster switch -

Electrical isolation of hot water unit

Electrical isolation of hot water unit -

Heat pump type hot water unit. These units harvest heat energy from the surrounding air.

Heat pump type hot water unit. These units harvest heat energy from the surrounding air. -

Hot water tempering valve

Hot water tempering valve -

How the tempering valve is part of the hot water supply system

How the tempering valve is part of the hot water supply system -

Control valves on the hot water system

Control valves on the hot water system -

Pipe lagging (or insulation) being fitted to copper pipes to conserve energy

Pipe lagging (or insulation) being fitted to copper pipes to conserve energy

- B1.2.1.

Quality control

- the water temperature is greater than 45°C at all tap points in the house, is stored at 60°C at the hot water system, and is tempered to shower, bath and basins tap points to a maximum of 50°C

- AT HANDOVER

FINAL COMPLETION

- AT HANDOVER

- the overflow from the pressure relief valve drains safely to ground

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

- COMPLETED DESIGN & SPECIFICATION

- the pressure relief valve does not drain to the roof or gutter to avoid corrosion

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

- COMPLETED DESIGN & SPECIFICATION

- the specified sacrificial anode and element has been provided

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

- COMPLETED DESIGN & SPECIFICATION

- the safety switch fitted on a dedicated circuit for the hot water service is working

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- COMPLETED DESIGN & SPECIFICATION

- all hot water pipes are lagged

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- COMPLETED DESIGN & SPECIFICATION

- hot water systems externally located in cyclonic or high wind areas are fitted with cyclone brackets and are protected from accidental damage.

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- COMPLETED DESIGN & SPECIFICATION

- cold water pressure relief, isolating valve and hot water pressure relief valves are fitted

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- that pressure relief valve drainage flows safely to the ground and away from the house and hot water system

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- an electrical isolation switch is provided on the roof for a roof mounted system or in the ceiling for a ceiling mounted system.

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- SOLAR: solar hot water collector panels are facing within 5° of north

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

- COMPLETED DESIGN & SPECIFICATION

- SOLAR: that solar hot water collector panels are mounted so that the angle of the panels from the horizontal plane is equal to the location's latitude, for example if the location's latitude is 30° south then the angle of the panels will be 30° from the horizontal plane

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

- COMPLETED DESIGN & SPECIFICATION

- SOLAR: trade test that the heat exchange fluid has been correctly added or replenished and the system is sealed

- DURING CONSTRUCTION

AT HANDOVER

TRADE TEST

- DURING CONSTRUCTION

- SOLAR: trade test that the solar booster has been connected if mains power is available

- DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- DURING CONSTRUCTION

- SOLAR: check that the solar panels are protected from stones and branches

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

- COMPLETED DESIGN & SPECIFICATION

- SOLAR: check that the solar panels are not shaded by buildings or trees.

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

- COMPLETED DESIGN & SPECIFICATION

- GAS: trade test that the system, all connections, fittings and the flu are located as required under regulations

- DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- DURING CONSTRUCTION

- GAS: check the gas installation has a compliance plate or certification.

- COMPLETED DESIGN & SPECIFICATION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- COMPLETED DESIGN & SPECIFICATION

- HEAT PUMP: trade test the heat pump hot water installation

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- HEAT PUMP: check the heat pump hot water system panel installation in 'split' type models - where heat exchange collector panels are separated from the cylinder

- COMPLETED DESIGN & SPECIFICATION

DURING CONSTRUCTION

AT HANDOVER

FINAL COMPLETION

TRADE TEST

- COMPLETED DESIGN & SPECIFICATION

- HEAT PUMP: check the heat pump hot water system fan and air filter pads in 'compact' type models

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- HEAT PUMP: check that the heat pump hot water system does not require additional refrigerant gas.

- AT HANDOVER

FINAL COMPLETION

TRADE TEST

- AT HANDOVER

- the water temperature is greater than 45°C at all tap points in the house, is stored at 60°C at the hot water system, and is tempered to shower, bath and basins tap points to a maximum of 50°C

Maintenance

As part of cyclical maintenance,

- check that the kitchen tap point delivers hot water at 55ºC and that all taps requiring tempered hot water deliver water to a maximum temperature of 50ºC.

- Plumber, Electrician, Local Maintenance Team, Gas Plumber

- 12 Months

- check that all pressure relief and isolating valves are functioning and arrange for a plumber to replace if required

- Plumber, Local Maintenance Team

- 12 Months

- check and re-fill the heat exchange fluid in solar hot water systems

- Plumber, Gas Plumber

- 12 Months

- check and repair lagging on all hot water pipes

- Plumber

- 12 Months

- replace the tap washers, as leaking hot water taps reduce the hot water available to residents and increase the household's energy bill.

- Plumber

- 12 Months

- the condition of the sacrificial anode and electric element and replace if required

- Plumber, Electrician

- 24 Months

- the main hot water storage cylinder for corrosion or build up of mineral salts

- Plumber

- 12 Months

- the hot water system thermostat is set at 60°C

- Plumber, Electrician

- 12 Months

- the condition of collector panels and the heat exchange fluid in solar hot water systems

- Plumber

- 12 Months

- the condition of collector panels or air filter pads of heat pump systems, and that the system is filled with refrigerant gas.

- Plumber, Gas Plumber

- 12 Months

- check that the kitchen tap point delivers hot water at 55ºC and that all taps requiring tempered hot water deliver water to a maximum temperature of 50ºC.

Standard And References

Centre for Appropriate Technology Inc. ‘Hot Water’ Bush Tech Brief #1, Our Place, 17, Winter 2002, Alice Springs, http://www.icat.org.au/documents/ op17.pdf

AS/NZS 3500.4:2021 - Plumbing and drainage - Heated water services

AS/NZS 3500.0:2021 - Plumbing and drainage - Glossary of terms

Lloyd, B, Wilson, L & Adams, A 2000, Hot water use and water heating systems in remote Indigenous communities, Centre for Appropriate Technology Inc.

Marshall, G. 1999, A review of Scale Prevention Devices for use in Hot Water Systems in remote Indigenous communities, edited by B. Lloyd, Centre for Appropriate Technology, Alice Springs

Lloyd, CR 1998, Hot Water Project Draft Progress Report, NTRC report cat no. 98/4, Centre for Appropriate Technology Inc., pp. 1-7.

Pholeros, P 1997, Energy and Water Use Required for Health in Housing on the Anangu Pitjantjatjara Lands North West of South Australia, for UPK Nganampa Health Council Inc., pp. 1-6.

Apunipima Cape York Health Council, Centre for Appropriate Technology Inc., Healthabitat and Pormpuraaw Community Council 1997, Pormpuraaw Housing for Health, Towards a Healthy Living Environment for Cape York Communities, project report, pp. 40-3.

Pholeros, P, Rainow, S. & Torzillo, P 1993, Housing for Health, Towards a Healthy Living Environment for Aboriginal Australia, Healthabitat, Newport Beach, pp. 45, 90-1.